turbine flow meter working principle ppt

Turbine flowmeters use the mechanical energy of the fluid to rotate a pinwheel rotor in the flow stream. The rotation of a pinwheel rotor can be sensed mechanically or magnetically.

Working Principle Of Turbine Flow Meter

The flowing fluid engages the rotor causing it to rotate at an angular velocity proportional to the fluid flow rate.

. Lets explain how a turbine flow meter works in detail. This principle is based on tracking multi bladed rotor rotation speed. With magnetic sensors the rotation of the turbine generates a pulse which is picked up by a sensor.

Blades on the rotor are angled to transform ener. The speed or rotation of the rotor is directly proportional to the rate of flowing gas. Working Principle of Turbine Flow Meter.

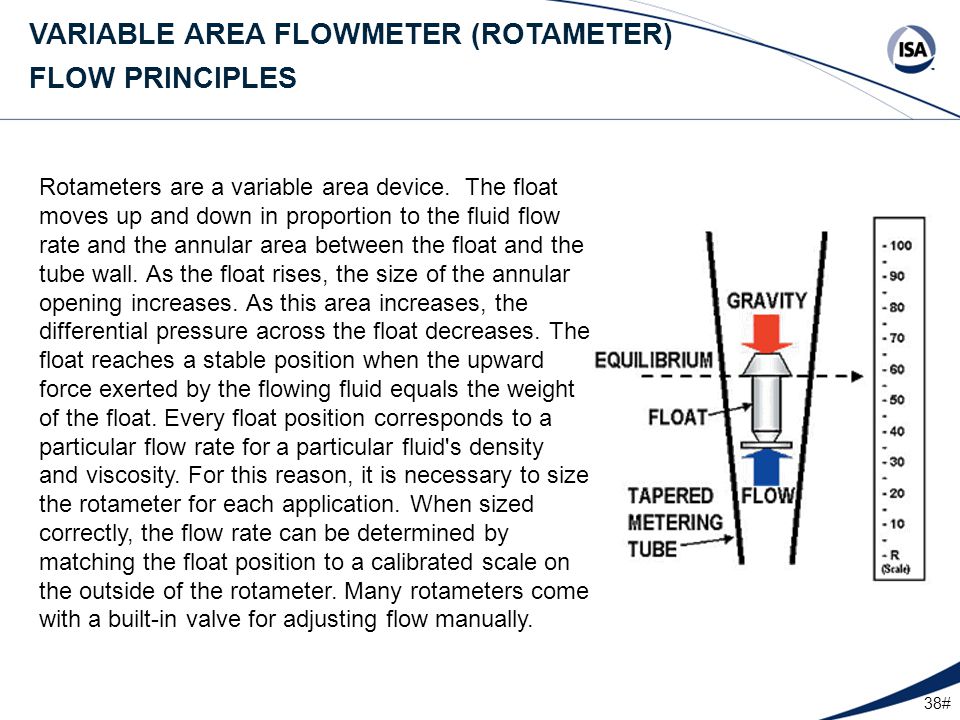

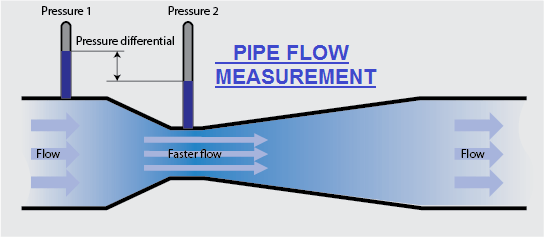

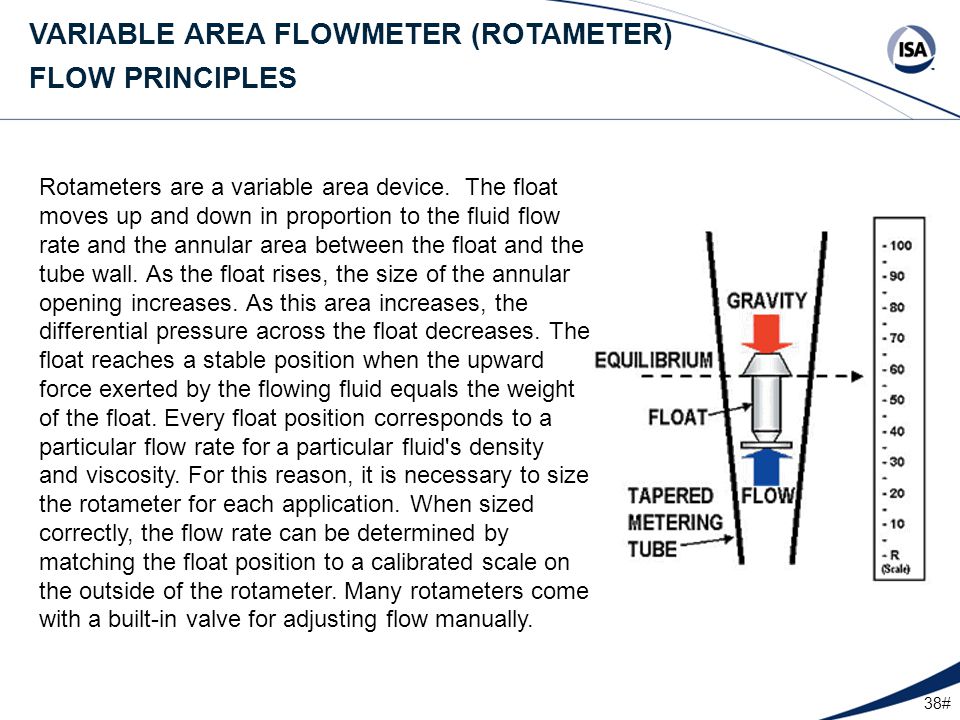

Orifice meter Venturi meter Rota meter Pitot tube. A reducer is used at the incoming side of the meter. The angular velocity of the rotor results in the generation of an electrical signal AC sine wave type in the pickup.

Turbine flow meters are ideally suited for low viscosity liquids. It consists of a multi-bladed rotor mounted at right angles to the flow and suspended in the fluid stream on a free-running bearing. Not suitable for very low flow rates.

A flow meter is a device that measures the flow rate of a fluid. What is a turbine flow meter how turbine flow meter work parts of a turbine flow meter advantages and disadvantages of turbine flow meter. Whereas the diameter and height of the turbine are 3 inches and 2 inch respectively.

PRINCIPLE Doppler flow meters operate similarly to the radar speed traps used on the road. Liquid flowing through a pipe causes the rotation of the internal paddle which creates a flow rate that is proportional to the rotational speed of the internal paddle. If this goal is achieved the turbine blades will achieve a rotating tip velocity directly proportional to the linear velocity of the fluid whether that fluid is a gas or a liquid.

The flow meter is highly accurate and often used for testing the performance of pumps engines valves and other flow meters. So how does a turbine flow meter work. In the case of the turbine meter the flowing gas velocity is represented by the rotation of the rotor itself.

Vortex Flow Meter Limitations. Turbine Flow Meter Construction and Working Principle in Hindi Flow Measurement by Turbine Flow Meter in Instrumentation measurement system -Watch Electro. Turbine flow meters use the rotation of a rotor within a flow tube to translate the flow of liquid into a readable rate.

The objective of our presentation is comparisons of different flow measuring devices. The ultrasonic waves strike particles moving. Vortex flow meters are suitable for a variety of applications and industries but work best with clean low-viscosity medium to high speed fluids.

When the fluid moves faster the rotor. An emitter sends ultrasonic waves at frequency f1 approx. The mechanical flow meter has a rotational device inside such as a paddle wheel or a propeller.

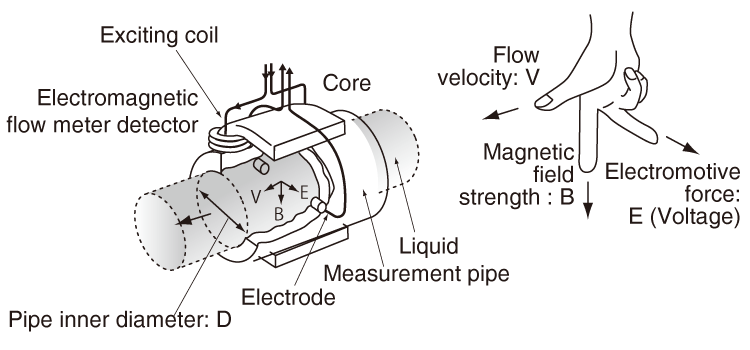

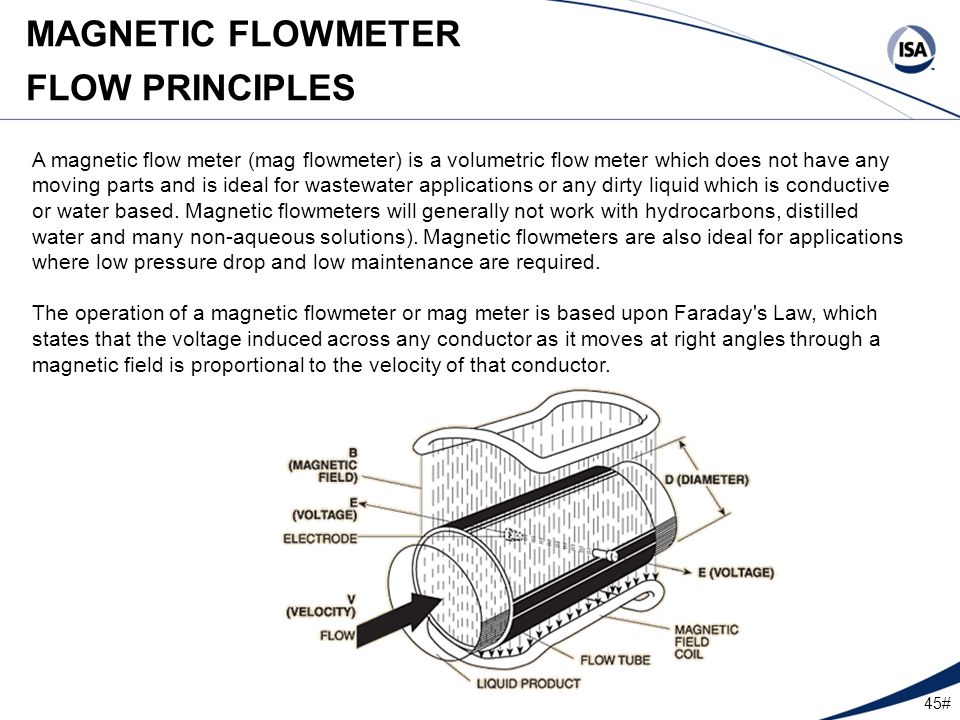

Flowing gas enters the inlet of the turbine meter and is immediately directed through a smaller channel created by. Principle of Magnetic Flow Meter Based on Faradays Law. The flow meter is characterized by simple structure high precision and easy installation and repair.

FLOW METERS A flowmeter or flow meter flow indicator flow gauge depending on industry is simply defined as a device used to measure the speed at which a gas or liquid is moving through a pipe. Accurate flow measurements of gases and liquids are required for the better control and quality of. The turbine meter is an accurate and reliable flowmeter for both liquids and gases.

The fundamental design goal of a turbine flow meter is to make the turbine element as free-spinning as possible so no torque will be required to sustain the turbines rotation. Minimum length of straight pipe is required upstream and downstream of the vortex meter. Turbine Flow Meter Turbine flow meter is a type of measurement meter which is use for measure of flow and provide exceptionally accurate and reliable digital outputs.

Turbine Flow Meter Working Principle. Flow meters are also known as Flow Gauges or flow measurement instruments. Turbine flow meter consists of turbine flow sensor and display instrument and it is made by us using foreign state-of-the-art technologies which is an ideal gauge for measuring of liquid flow.

Turbine flow meter is used for translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user readable rate of flow. The blades on the rotor are tilted at a certain angle like a propeller to convert the energy from the fluid flow into rotational energy. The product may be used in a wide range of industries including oil industry chemical.

Vortex Flow Meter Applications. The faster you pedal the faster you move. Blades on the rotor are angled to transform energy from the flow stream into rotational energy.

TURBINE FLOW METER Installation and Operation Guide 0721-5 13518 09-15 FLOW AND ENERGY MEASUREMENT. Working Principle of Turbine Flow Meter 1. Magnetic flow meters works based on Faradays Law of Electromagnetic Induction.

The rotor shaft spins on bearings. Turbine Flow Meter is a volumetric measuring turbine type. According to this principle when a conductive medium passes through a magnetic field B a voltage E is generated which is proportional to the velocity v of the medium the density of the magnetic field and the length of the conductor.

Such method is very similar to cycling. Complete knowledge of their trade skills and are competent to work on high pressure hot and cold water systems. The rotor shaft rotates on a bushingbearing where as the fluid moves faster the rotor rotates proportionally faster.

Flow meters are flow measuring instruments used to measure the linear nonlinear mass or volumetric flow rate of a gas or a liquid. Working Principal Turbine meters are inferential measurement devices that measure a flow rate indirectly by using the natural kinetic energy of the flow as it passes through the angled blades of the turbine rotor. The most diverse substances are transported and distributed in piping system in every single day they may include solvents chemicals oilgas drinking water fruit juices slurries etc The fluid flowing through.

Flow of liquid or gas acts as a driving force and turbine rotor as the wheels. How the Turbine Flow Meter Works. Length of the rectangular box is 12 inches.

The mechanical flow meter is easier for laymen to understand. 1 - 5 MHz at angle a into the flowing product.

Electromagnetic Flow Meter Flow Knowledge Keyence America

Centrifugal Pump Types Centrifugal Pump Pumps Pump Types

Working Principle Of Turbine Flow Meter

Working Principle Of Turbine Flow Meter

Turbine Flow Meter Explained Operation And Calibration Realpars

Gas Flow Measurement Types Applications Of Flow Sensors

Mark Murphy Pe Technical Director Fluor Corp Ppt Download

Electromagnetic Flow Meters Working Principle Instrumentationtools

Working Principle Of Turbine Flow Meter

Gas Flow Measurement Types Applications Of Flow Sensors

Turbine Flow Meter Working Principle Instrumentationtools

Working Principle Of Turbine Flow Meter

Turbine Flow Meter Working Principle Instrumentationtools

Mark Murphy Pe Technical Director Fluor Corp Ppt Download

Mass Flow Meter What Is It How It Works Types Accuracy

Working Principle Of Turbine Flow Meter

Jis And Bsp Fittings Usage Leakage Problems Fittings Vacuum Cleaner Problem

Measuring Or Working Principle Of Turbine Flow Meter Youtube